Buttweld Fittings.

What Are Buttweld Fittings?

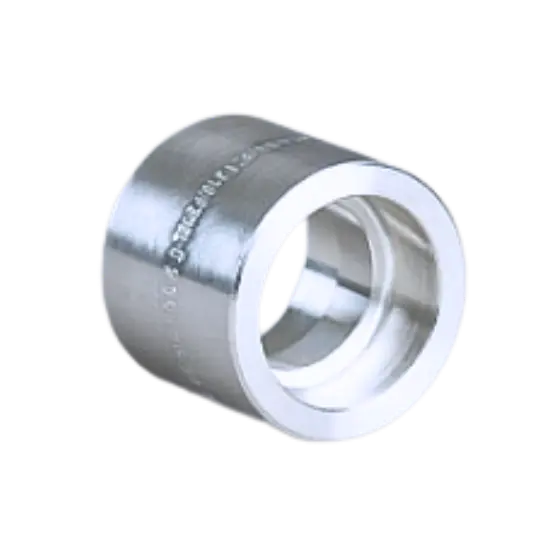

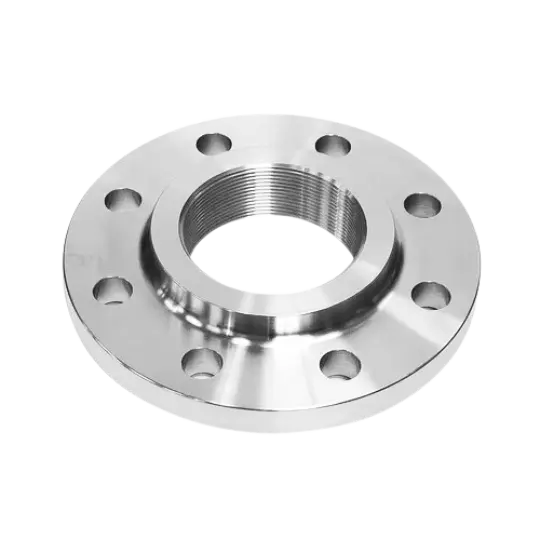

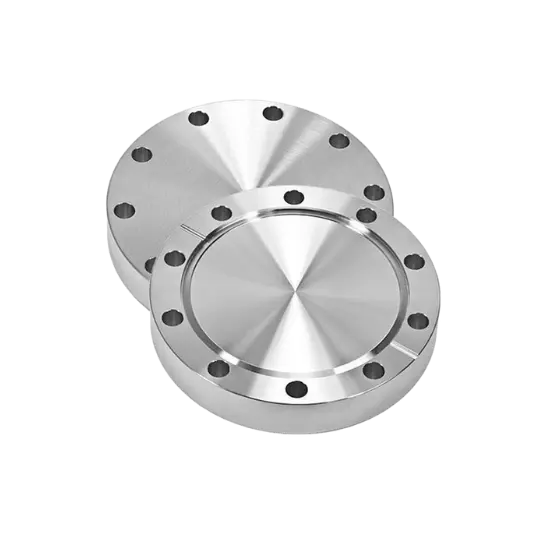

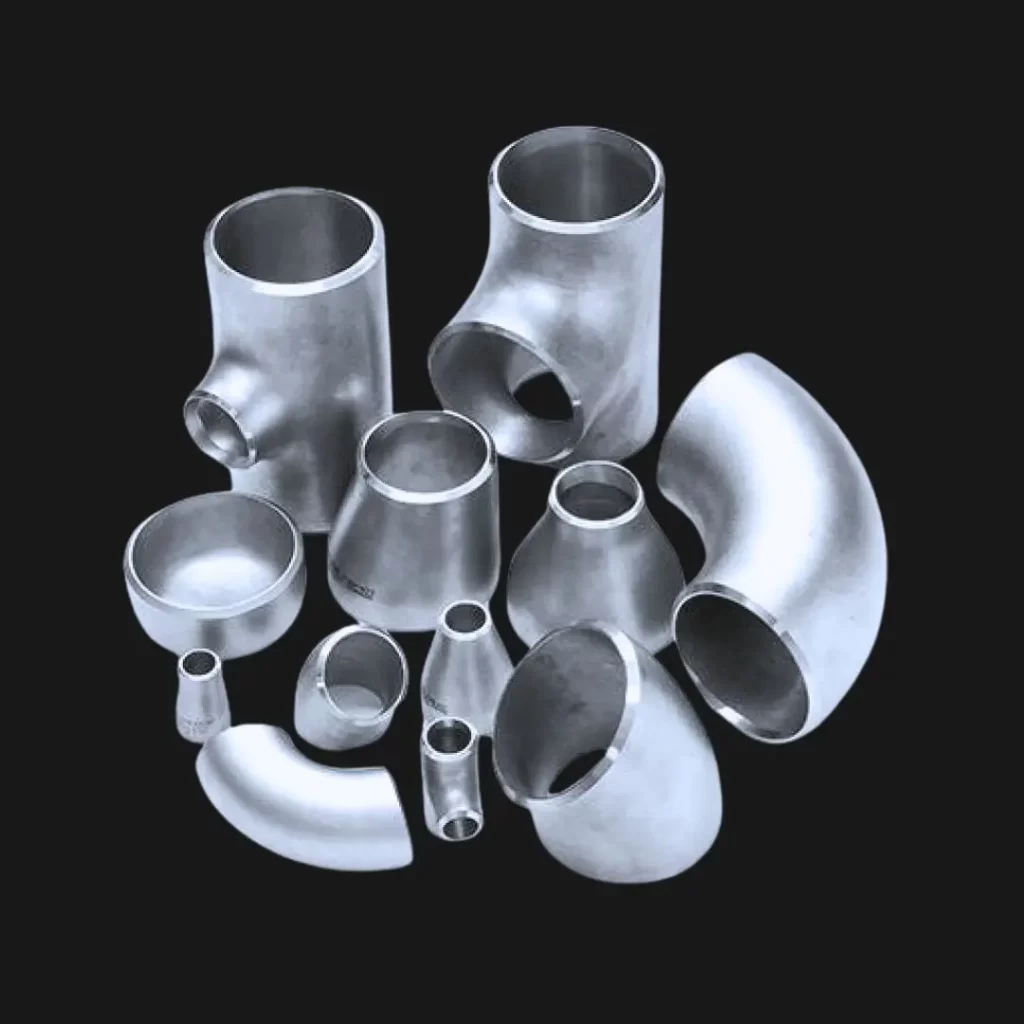

Butt weld fittings are essential components in industrial piping systems, designed to create strong, seamless connections by welding the beveled ends of two pipes, fittings or flanges together. This continuous weld around the joint’s circumference ensures superior structural integrity and leak-proof performance.

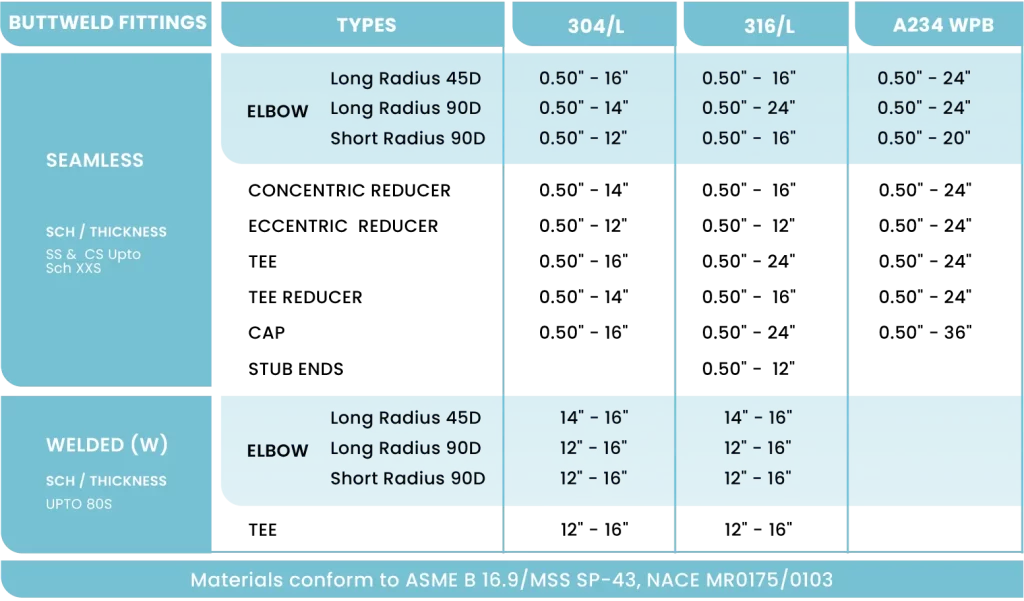

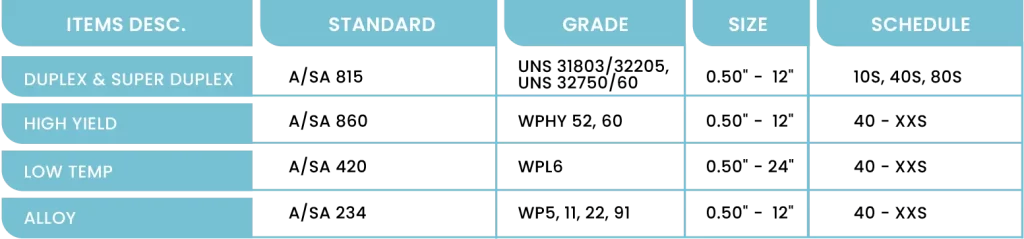

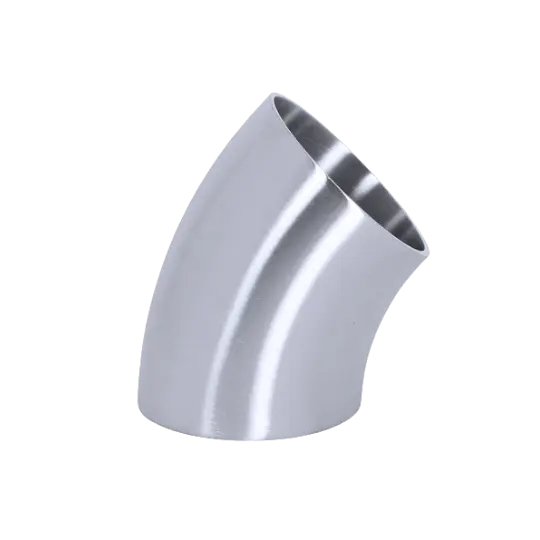

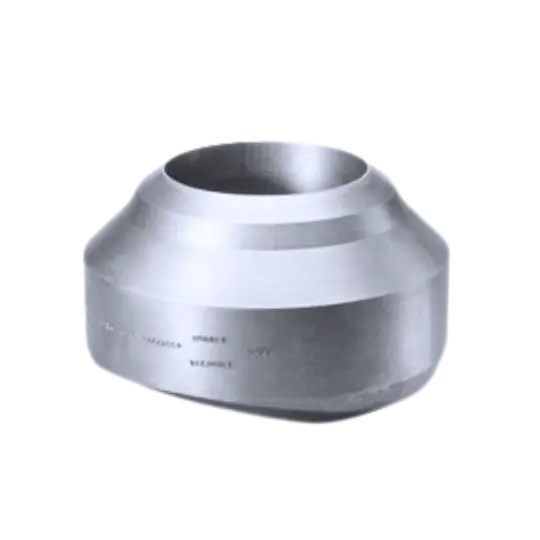

Available in various materials such as carbon steel, stainless steel, duplex, and alloy steel, butt weld fittings come in multiple configurations, including elbows (45° and 90°), tees, reducers, caps, and crosses. Each type plays a crucial role in optimizing fluid flow and system design in high-pressure and high-temperature applications.

Advantages of Buttweld Fittings?

Superior Structural Strength

The welding process forms a continuous metal structure, enhancing system durability and reliability.

Leak-Proof Performance

A fully welded connection eliminates the risk of leaks, ensuring a secure and long-lasting joint.

Optimized Flow Efficiency

Smooth inner surfaces and gradual directional changes reduce pressure loss, minimize turbulence, and prevent corrosion and erosion.

Compact & Space-Saving Design

Ideal for installations where space is limited, offering a more streamlined piping system.

Brands We Carry.

Fill out the form, and our team will get back to you within 24 hours.

Submit Your Inquiry.